Lately I do not have too much free time to dedicate to the moto2 design. These days previous to the CEV start we are training almost every week. Last week we were in Albacete and this week we will be in Valencia.

Anyway I am already working on the chassis design. Currently I am working on several different concepts. What I do with each one is to study in a very rough way its 3 main stiffnesses:

- Chassis torsional stiffness around the fore-aft axis of the bike.

- Chassis torsional stiffness around a transverse axis of the bike (this is the chassis stiffness during braking).

- Chassis lateral flexing stiffness.

For sure you already know that current trend in chassis design is to have a “high” stiffness in cases 1 and 2 and some controled flex in the third one.

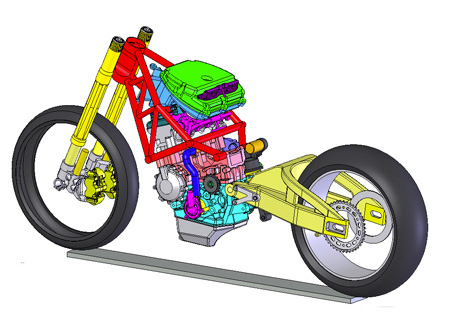

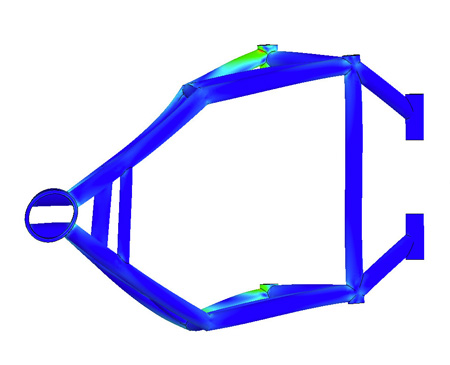

Normally I draw each idea directly in 3D. For example, regarding the concept you can see below, I knew that it wouldn’t work because it is too stiff in side flexing, anyway I liked the very direct connection between the headstock and the engine mounting points, so I drew it and I made a very simple FEA analysis in order to have a first idea about the stiffness values for each case. I think that to study several different ideas is interesting because it allows me to “locate” each concept with respect to the others, and that gives me a better understanding of the behaviour of each concept.

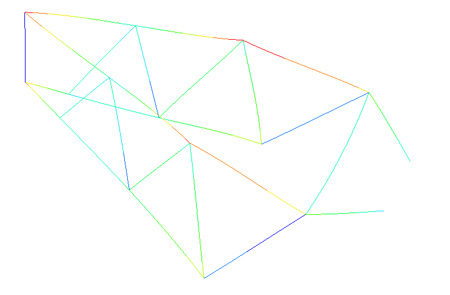

This is a very simple FEA, using “bar” elements.

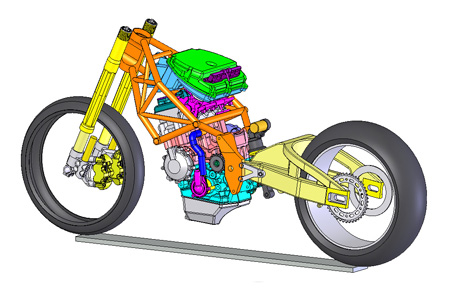

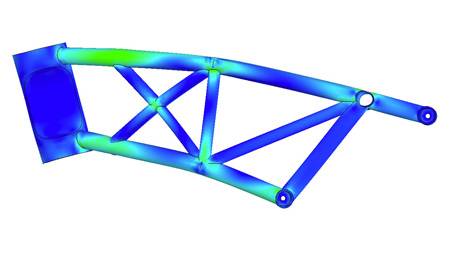

The next concept has a less direct connection and a not so compact design, but however it has a more interesting behaviour regarding stiffness. Like you can see I didn’t draw the triple clamp or the rear suspension yet. The rear area of the chassis (swingarm clamping area) is just roughly sketched and incomplete. The airbox is still the ZX6 original (of course we must design a new one). Ah! The swingarm is the Morlaco one.. till we design the new one this one has to do. 🙂

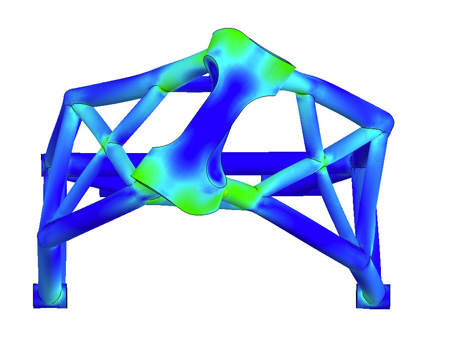

I made a more complex FEA model of this concept, although it is not yet a very elaborated one.

Torsional stiffness.

Lateral flex stiffness.

Lateral flex stiffness.

Braking stiffness.

One thing that you can see in these drawings is the headstock design, with two cut outs at both sides to let room for the airbox intake. This design is used in the Ducati Motogp or in the Kalex. I think it is a very good compromise between efectivity and simplicity.

Probably the final design of the chassis will be very different compared to what you see in these images, this is just an example, I am working on several different concepts.

One of the things that I like more of this process is that in the beginning I have no idea about how the bike is going to be, and by working and thinking on the ideas, the bike starts appearing gradually.

I remember that more than 20 years ago I read an Alan Cathcart’s article about the Fior Rotax 250 GP from 1987 (Claude Fior is one of the designers I admire a lot), I think his 1987 two fifty is one of the most brilliant designs ever. Fior said: “I always thought that the motorbikes design themselves. In reality the only thing I do is translate to tubes and plates what they are telling me“.

Hi, This is very interesting work on the analysis of the tube layout. I have built a few chassis in my time and have recently begun using solid works. I would like to design my next bike entirely in 3D before I start to cut and weld, and would also like to do a 600cc moto2 based bike, but cannot find a source of cad models for the engine/airbox. Could you point in the right direction in finding one. If you would like to have a look at some of my projects, just type in MRicci into Google and find my facebook photo album page.

Regards

Mario