Bottpower’s Mechanical Engineering services blend innovation with practical solutions, focusing on creating motorcycles that impress both in aesthetics and performance. Our expert team skillfully transforms concepts into reality, tailoring each project to its unique requirements. From bespoke frames to efficient suspension systems, we ensure every design is a perfect mix of individuality, efficiency, and cost-effectiveness. We work collaboratively with our clients, ensuring that the final product not only fulfills but surpasses their expectations. Opt for Bottpower to take your motorcycle’s design and performance to new heights.

At Bottpower, our Advanced Motorcycle Mechanical Engineering services encompass a wide range of specialized activities, each aimed at pushing the boundaries of motorcycle performance and design. Here are some key examples of our expertise:

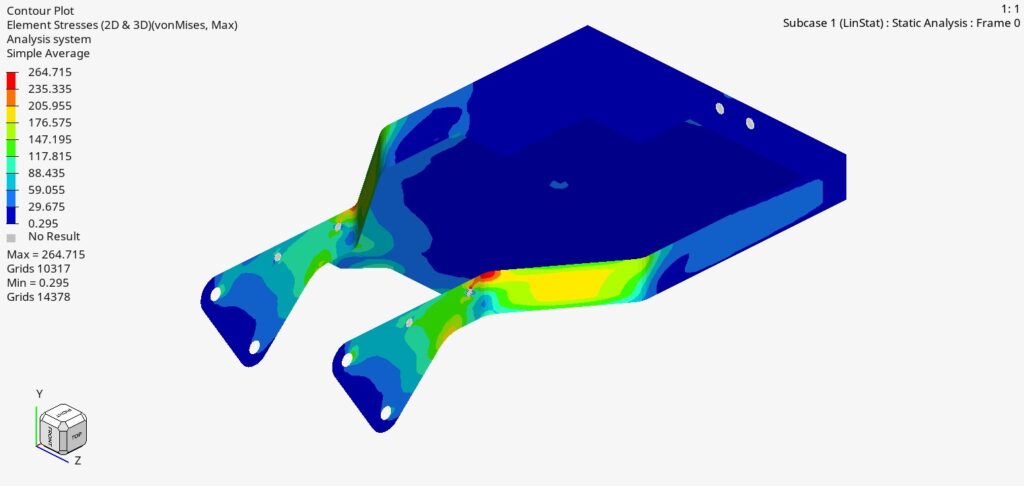

Finite Element Analysis (FEA):

At Bottpower, we utilize Finite Element Analysis (FEA) to predict how new motorcycle designs will respond to forces and stresses. This advanced computational technique allows us to model and analyze the structural integrity of components before they are physically built, ensuring optimal strength and durability while minimizing weight.

Topological Optimization:

Our topological optimization process is a key element in sustainable motorcycle design. Through this method, we meticulously refine the geometry of motorcycle components, focusing on the efficient distribution of material to achieve an optimal strength-to-weight ratio. This approach not only enhances durability but also contributes to lower fuel consumption and reduced emissions, making it crucial for creating environmentally friendly motorcycles where every gram has an impact.

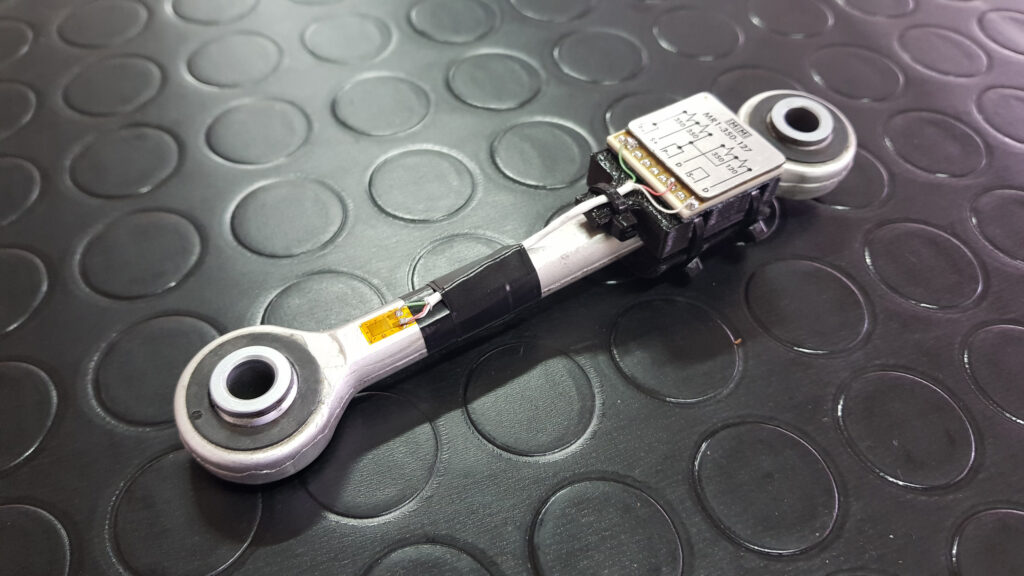

Component instrumentation:

Instrumentation of components is a key part of our mechanical engineering services. We equip motorcycle parts with sensors to measure performance under various conditions. This data is invaluable for refining designs and ensuring each component performs at its peak in real-world scenarios.

Prototype fabrication:

At Bottpower, our expertise in prototype fabrication is extensive, covering a range of sophisticated techniques to bring motorcycle concepts to life. We specialize in machining, TIG welding, working with composites, and utilizing 3D printing technologies. This blend of traditional and modern methods allows us to create detailed, high-quality prototypes that precisely match design specifications. Our hands-on experience ensures that each prototype not only looks the part but also functions seamlessly, providing a solid foundation for final production.