From February to June, we had the pleasure of hosting Mike Zwirs at Bottpower for his graduation internship. Mike is a mechanical engineering student from the Netherlands, and he joined us to complete his bachelor’s thesis through a project that combined technical depth with creative engineering.

Mike’s work focused on the design of an alternative upright for a front suspension system using 3D-printed titanium. The aim was to explore new ways of optimizing geometry and performance by taking full advantage of the design freedom offered by additive manufacturing.

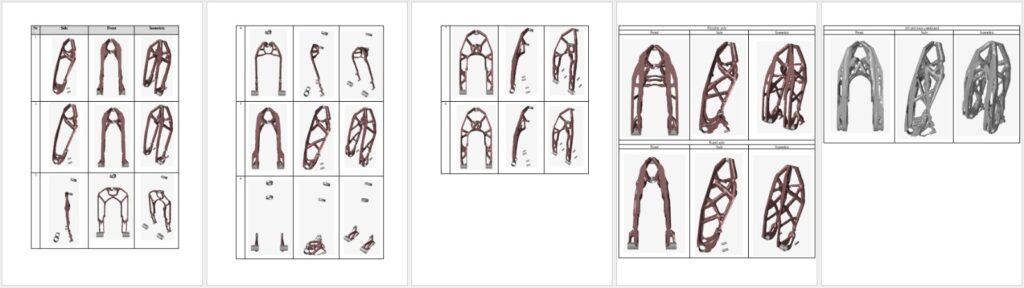

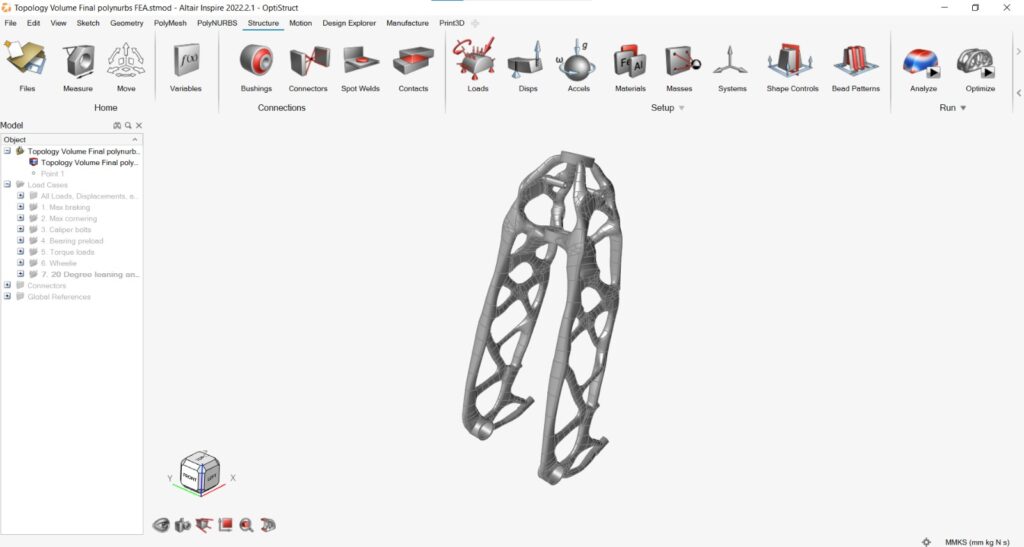

The project began with a research phase, where Mike reviewed existing studies on suspension designs and load paths. He then created a range of design volumes and used topology optimization tools to analyze them. This allowed him to identify how the structure could efficiently handle the forces involved. After comparing the different solutions, he selected the most promising one and turned it into a printable geometry using Altair’s Polynurbs.

Throughout the project, Mike worked with tools from the Altair software suite, which played a key role in both the optimization and design refinement phases. In parallel, we also collaborated with Optimus3D, who provided us with valuable technical input related to additive manufacturing. Their support included detailed information on printing strategies, material behavior under load, build orientation, and parameters affecting both structural performance and print feasibility. This collaboration added a layer of realism and manufacturing insight to the project that is often missing in academic work.

While this design won’t be used in the current front suspension prototype we’re building for the Morlaco 2, the insights gained during the project are already influencing our future developments. The work on load management, geometry and 3D-printing strategies has been extremely valuable.

Here’s how Mike described his experience:

“This spring semester, I finished my graduation internship at Bottpower, where I worked on my thesis for my bachelor’s in mechanical engineering. Since I’ve always been into motorcycles, it was an interesting company to do my final project.

During my internship my project was to design an alternative front suspension upright using 3D-printed titanium. I started by researching existing studies and then created different design volumes to run topology optimizations on. These helped me understand how the loads were distributed and how the geometry reacted. After comparing the results, I picked the most promising one and rebuilt it into a smooth, printable model using Altair’s Polynurbs tool.

Because printing the part as a single piece would be difficult, I decided to split the design into three sections. That way, each part could be printed in the most suitable orientation and, if needed, even be made from different materials for performance or visual reasons.

For me, this was a challenging but interesting project. It was a good mix of technical research, design decisions, and practical constraints. I also got a look into how Bottpower approaches their projects: Driven by performance, innovative and open to unconventional designs. That way of working suits me well. David has a lot of experience, which I was able to learn a lot from. Especially when it comes to translating theory into real motorcycle components and understanding geometry and bike handling. Being in the workshop surrounded by both current and past projects also added to the experience, it was great to see those designs up close in real life.

Living in Valencia during the project was a great experience too. With Bottpower’s shop located on the Ricardo Tormo Circuit there was always something happening on track, varying from race motorcycles to hypercars. A highlight was visiting the Aspar-Ksb team’s pit box during a training session, where you could really see how motorcycle engineering is put into practice at a professional level.”

From our side, it’s been a real pleasure to work with Mike. He approached the project with a strong sense of responsibility and curiosity, and showed a clear passion for engineering and motorcycles. We’re happy to have had him as part of the team during these months. We wish him all the best in the next steps of his career and we’re sure our paths will cross again.