We now have in our hands the first Morlaco 2 titanium fork, 3D printed and ready for testing. After months of design work, simulations, revisions, and adjustments, holding a part like this always brings a special feeling — a tangible reminder that the project is moving forward, step by step.

The fork is made up of three parts. The upper section, which houses the steering head bearings, is bolted to the two side arms. At the lower ends of these arms are the wheel axle and brake caliper mounts. We aimed for long and relatively narrow arms to be able to fine-tune their lateral stiffness. One of the potential advantages of this type of front end, compared to a conventional telescopic fork, is precisely the ability to control lateral stiffness more precisely.

In the case of racing motorcycle swingarms, this kind of stiffness tuning has been used for a long time: they combine high vertical (and torsional) stiffness with lower lateral stiffness, which allows a degree of controlled flexibility when the bike is leaned over. Telescopic forks are more limited in this respect, and this is where an alternative front-end design like the one on the Morlaco 2 can offer some advantages.

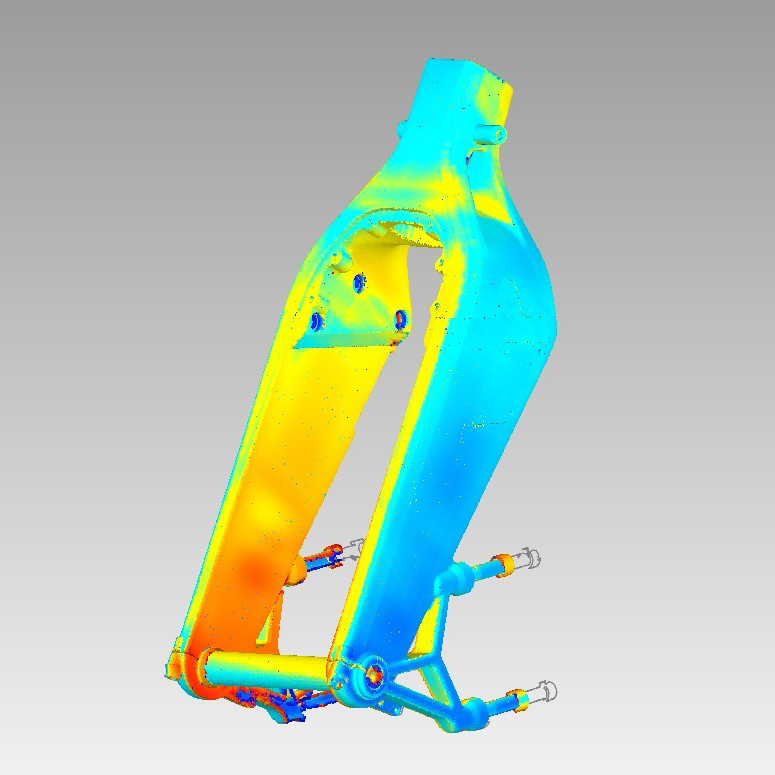

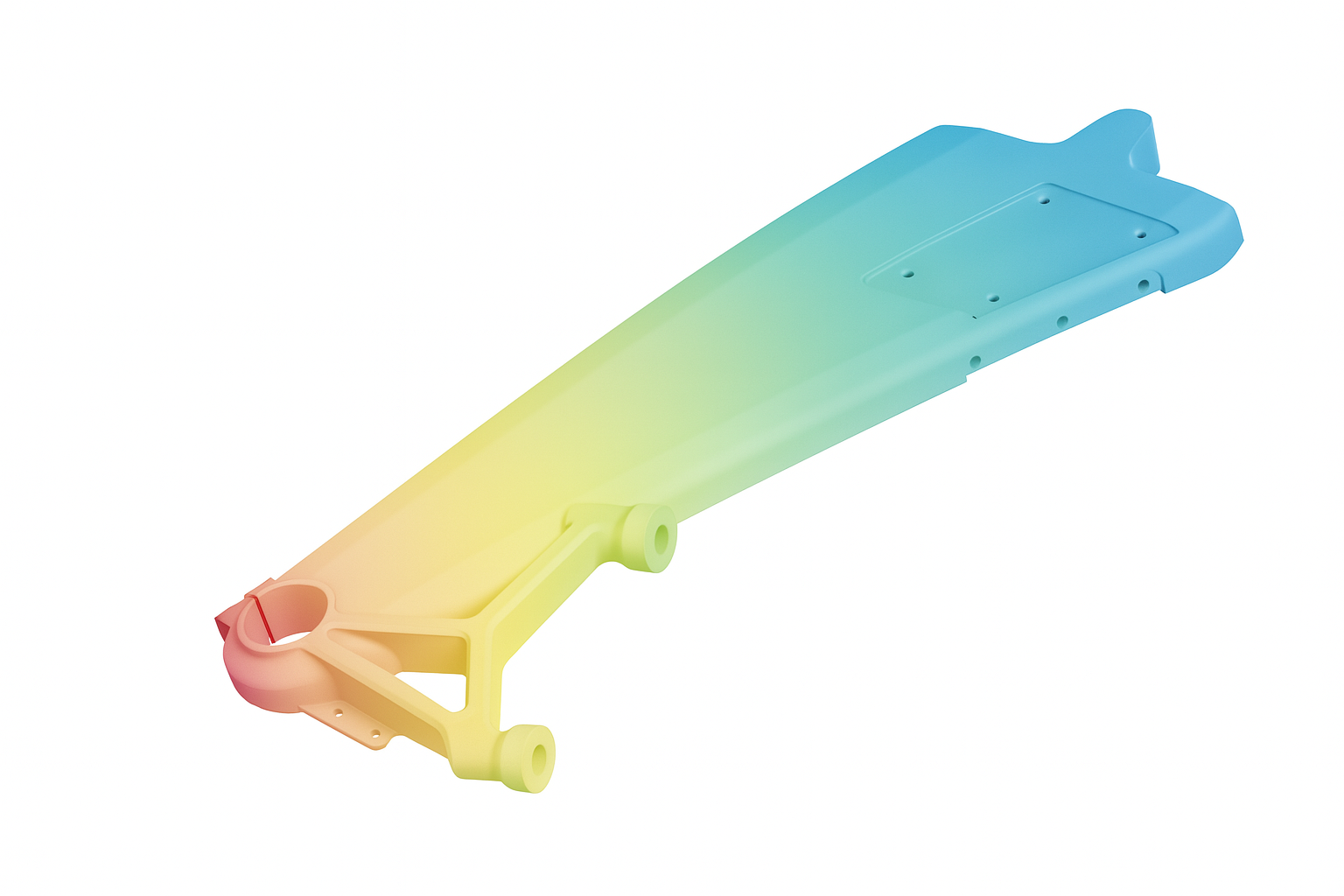

Since we still have limited experience with large titanium-printed parts, the Morlaco 2 titanium fork was 3D scanned to verify the printed geometry against the CAD model.. This analysis helps us not only to measure the magnitude of any deviations but also to understand their nature. For this work, we collaborated with Realtodigital, specialists in 3D scanning.

The image below shows the CAD model and the scanned part overlaid. The light blue areas correspond to the CAD model, while the yellow, orange, and red colors represent the real part. The largest differences are found around the wheel axle area.

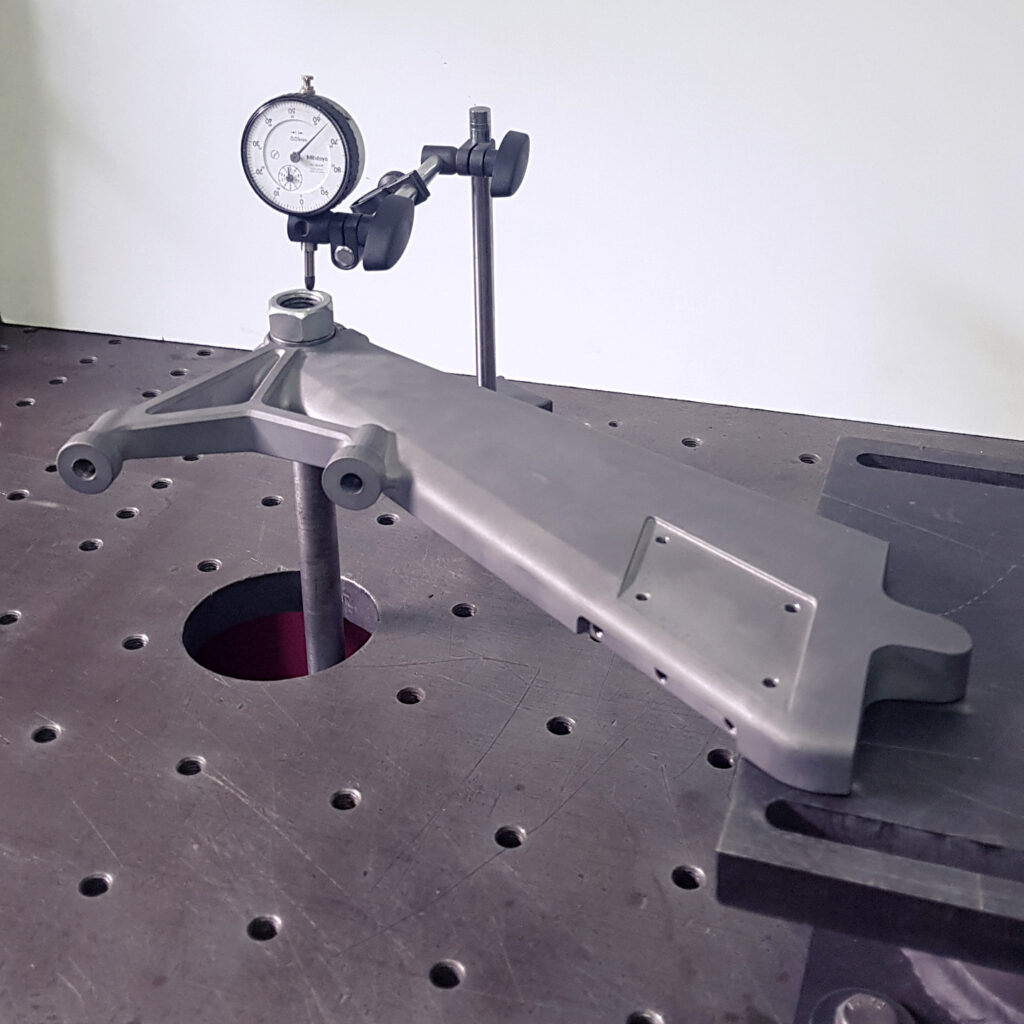

We also performed a lateral stiffness test on one of the fork arms. It’s a simple but very informative test: a progressively increasing lateral load is applied while measuring the deflection with a dial gauge. This allows us to obtain a force–displacement curve that can be compared with the results of our finite element model.

The correlation between the model and the test has been very good, which reinforces our confidence in the simulation and allows us to evaluate future variants with greater reliability.

We continue to move forward step by step, but this fork represents a small victory: a complex, structurally demanding, and unconventional part that is starting to come to life beyond the screen. 😊