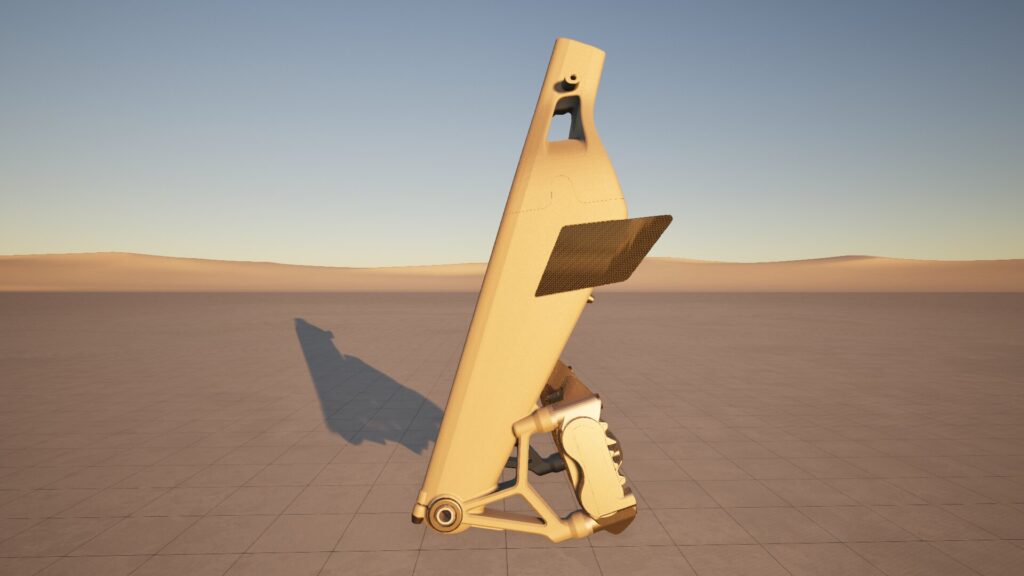

In a previous post, we shared a first concept image of the Morlaco 2 — a motorcycle that aims to reinterpret some of the design principles we explored with the original Morlaco. Today, we’d like to show how we’ve been refining and developing that initial concept, staying true to its core ideas: a non-conventional front suspension, a fuel tank that also functions as a subframe, and an exhaust system integrated into the belly pan.

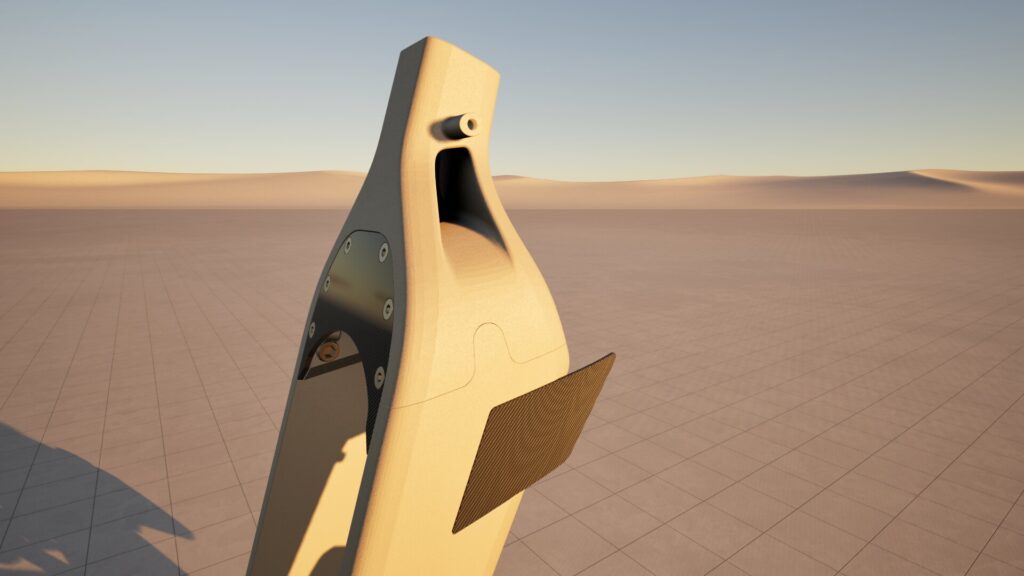

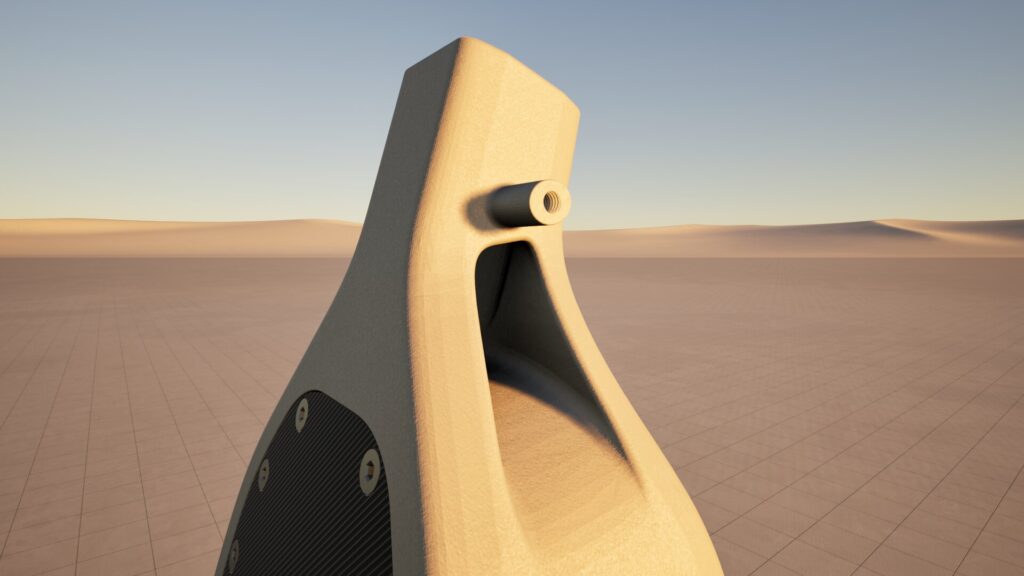

We’ve explored several variations of that initial proposal, without straying far from its essence. For example, the front section of the tank (which is actually part of the airbox) has been redesigned to give it a more refined and coherent shape.

As for the fork, we’re working on different options. One of them is a multitubular structure, visually related to the one we used on the original Morlaco.

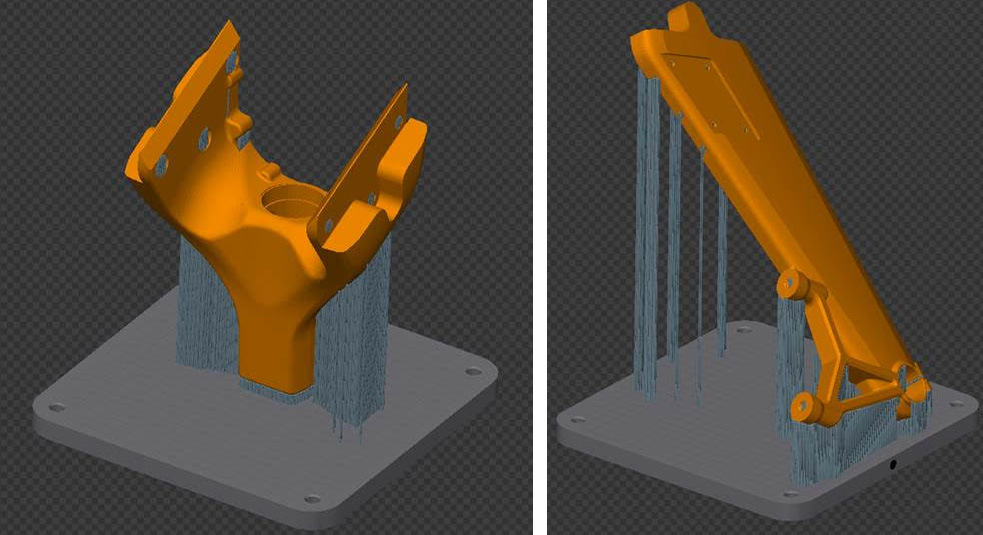

Another is a titanium-printed fork, developed in collaboration with Optimus3D — the same company we partnered with to print the dashboard bracket on the Morlaco 1.

This new fork consists of three parts: a central piece that houses the steering axis and two side pieces bolted to it. The images below show the design with support structures that will be removed after printing.

Using 3D printing gives us total design freedom. We can vary wall thicknesses, add internal reinforcements, or even lattice structures to increase stiffness where needed. This allows us to control how the fork deforms under load — for example, adjusting lateral stiffness when the bike is heavily leaned over. It’s an area where this front-end layout can offer advantages over a conventional telescopic fork.

The fork legs are quite long, which helps manage flex. We’ve also added a bolted top plate. By adjusting its shape, thickness, and material, we can further fine-tune the structural behavior of the assembly.

To develop all of this, we’re using Altair HyperWorks — a powerful simulation suite that allows us to evaluate how each component behaves before manufacturing. We’ve run many finite element simulations and topological optimizations to better understand the ideal shape of each fork component.

Meanwhile, Reynolds Technology has sent us the first batch of tubes to build the initial chassis prototype. We already collaborated with Reynolds back in 2010 when developing our Moto2 bike, and we’re thrilled to work with them again. Reynolds specializes in high-performance tubing, with a wide range of advanced alloys and technologies like variable wall thickness — something we’re also keen to experiment with in this project. We’ve already started cutting tubes and will begin building the first frame soon.

We’re also making good progress on the 3D design of the fairing, airbox, fuel tank, and tail section. Besides the work of Hugo van Waaijen, a key member of Bottpower since the beginning, we’re now also collaborating with Nick Graverley, who has introduced us to his virtual reality workflow. A fascinating experience — we’ll talk more about it in the next post.

We keep moving forward, step by step, combining experience, simulation, and technology to bring to life a motorcycle we’re truly excited about! 😊

hi

Where you fill up your fuel tank?

If, from the top you will have problem to fill up correctly.

Don’t hesitate to ask me advice.

Welcome.

Hi Geney,

Yes, the plan is to fill it from the top. A few years ago, we designed and built a Moto2 bike with a very similar fuel tank, and we didn’t have any issues with refueling.

That said, I’m genuinely curious about your advice, happy to hear your thoughts. 😊