The airbox intake is one of the M210 parts that was not designed yet. In most race bikes this part is made using carbon fiber (CF). By the moment we have designed it to be fabricated using Selective Laser Sintering (SLS). Fortunately for this task we have the support of Ineo, a Spanish company specialized in rapid prototyping.

Using SLS technique allows us to have the part fabricated in a few hours, without having to make moulds like it happens with CF. Another advantage of SLS is that we have a lot of design freedom because we can design the part adding details and forms that would be impossible to fabricate even using a CNC milling machine.

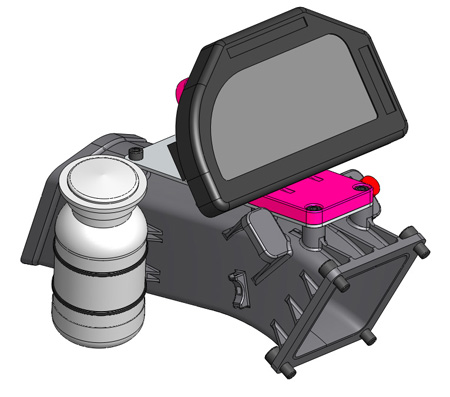

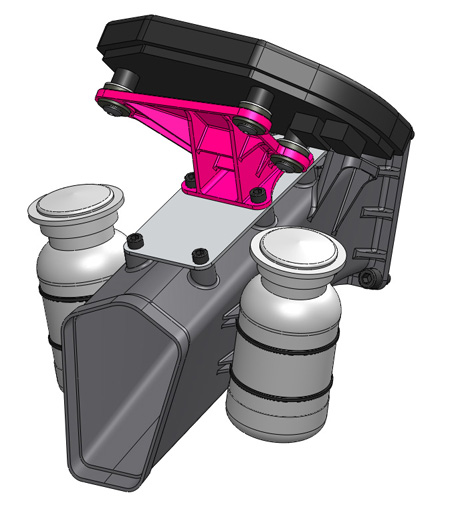

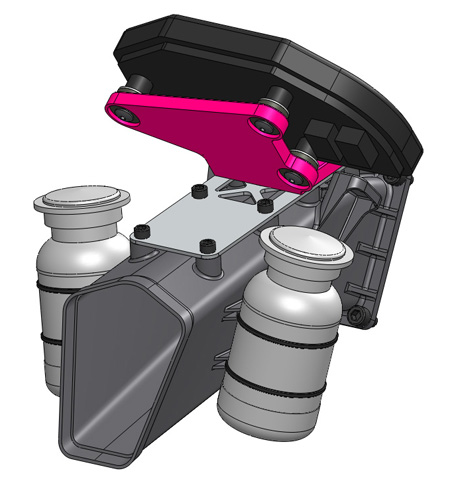

In this way it is easier to design the part so that it can serve several functions:

– Introduce fresh air into the airbox.

– Hold the bottles for the leftover water and fuel.

– Provide a solid clamping point for the nose of the fairing.

– Provide multiple clamping points for the electrical cables.

– Provide adequate clamping for the connector that is used to download telemetry data. The same connector is used also to manage the engine maps and electronic strategies of the bike.

– Provide a platform to clamp the display bracket and the spider that holds the fairing around the windscreen.

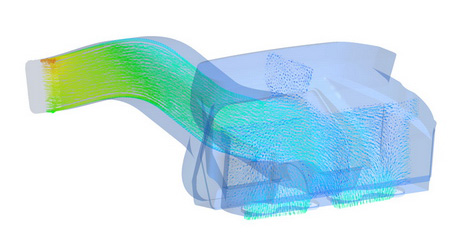

The overall geometry of this part was determined some months ago based on CFD (Computational Fluid Dynamics) studies.

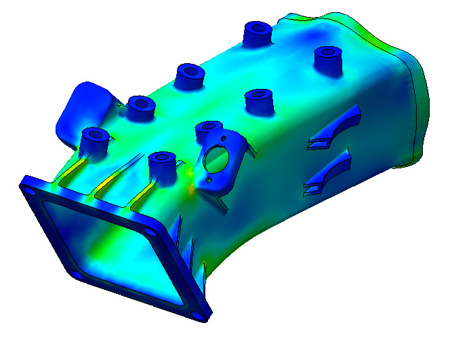

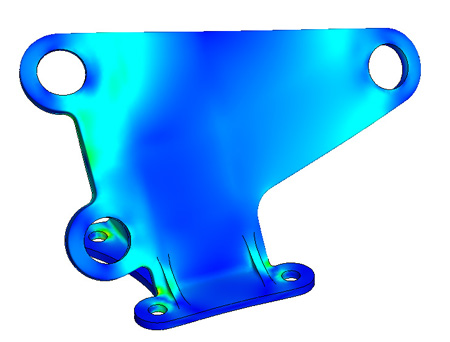

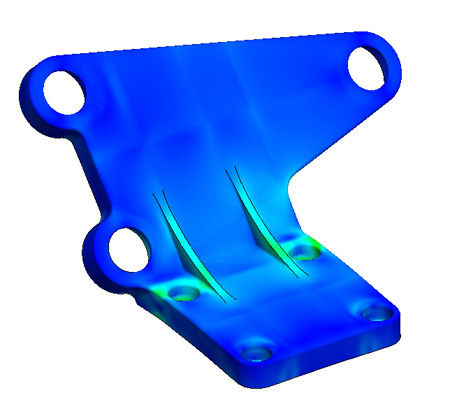

Using finite element analysis we can design the part to minimize its weight, we can also use a variable thickness to put the material only where is necesary, we can add ribs, etc.

In this way it is possible to design a part that has a weight very similar to a CF part, specially if we consider that in the CF part we should add several inserts and small pieces to clamp the various elements that are around it.

For the part that supports the display (pink colour) we studied two different designs. We must decide which design we want to use and then send an email to Ineo with the geometry of the part, in that way we will have the part ready to assembly on the bike in a few days.

This is the first design:

This is the second design, a hollow part with ribs inside.

Next week I hope to show you pictures of these parts already manufactured.